Anodizing

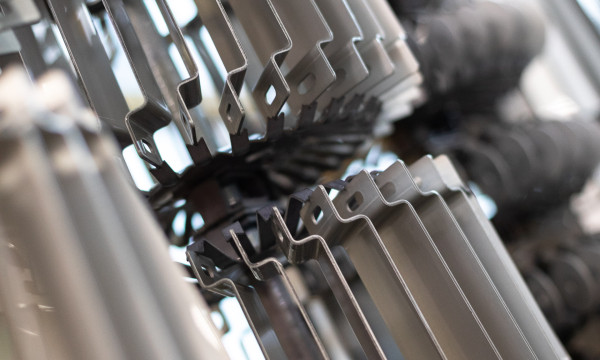

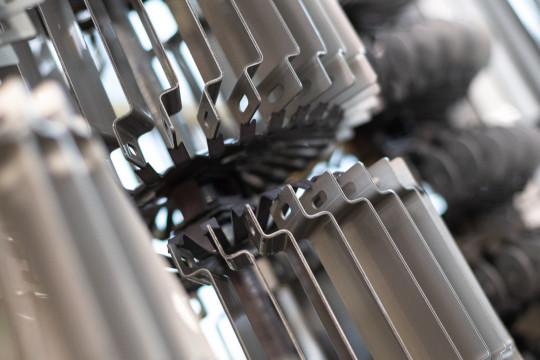

Anodizing, also known as anodization or anodic oxidation, is an electrolytic process used to create a protective oxide layer on the surface of components. Anodizing is primarily performed on aluminum alloys. The thickness and color of the layer depend on the aluminum alloy substrate and the operational conditions of the anodizing process. The resulting oxide layer enhances the functional properties of the aluminum alloy, particularly increasing corrosion resistance, hardness, and abrasion resistance of anodized parts.

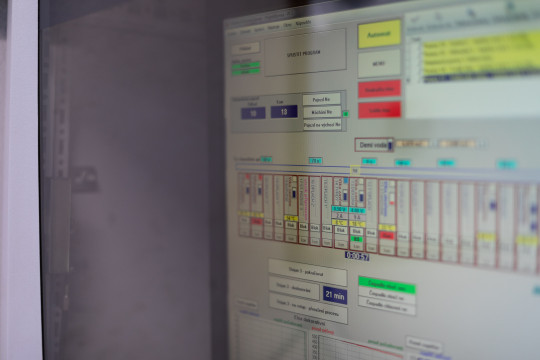

Anodizing is environmentally friendly because it reinforces the natural oxidation of aluminum, thus avoiding the production of heavy metals or other harmful and hazardous by-products. Bomex operates an anodizing technology using a sulfuric acid solution.