JAMP SVORADA, s.r.o.

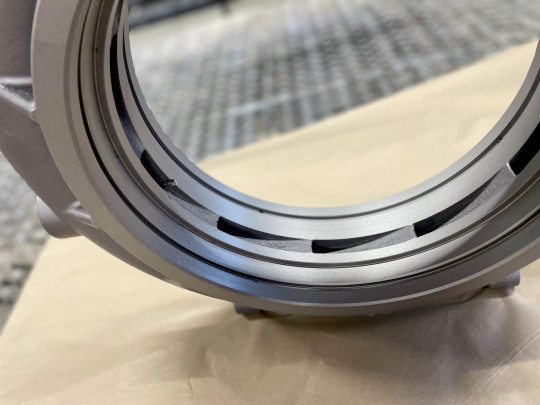

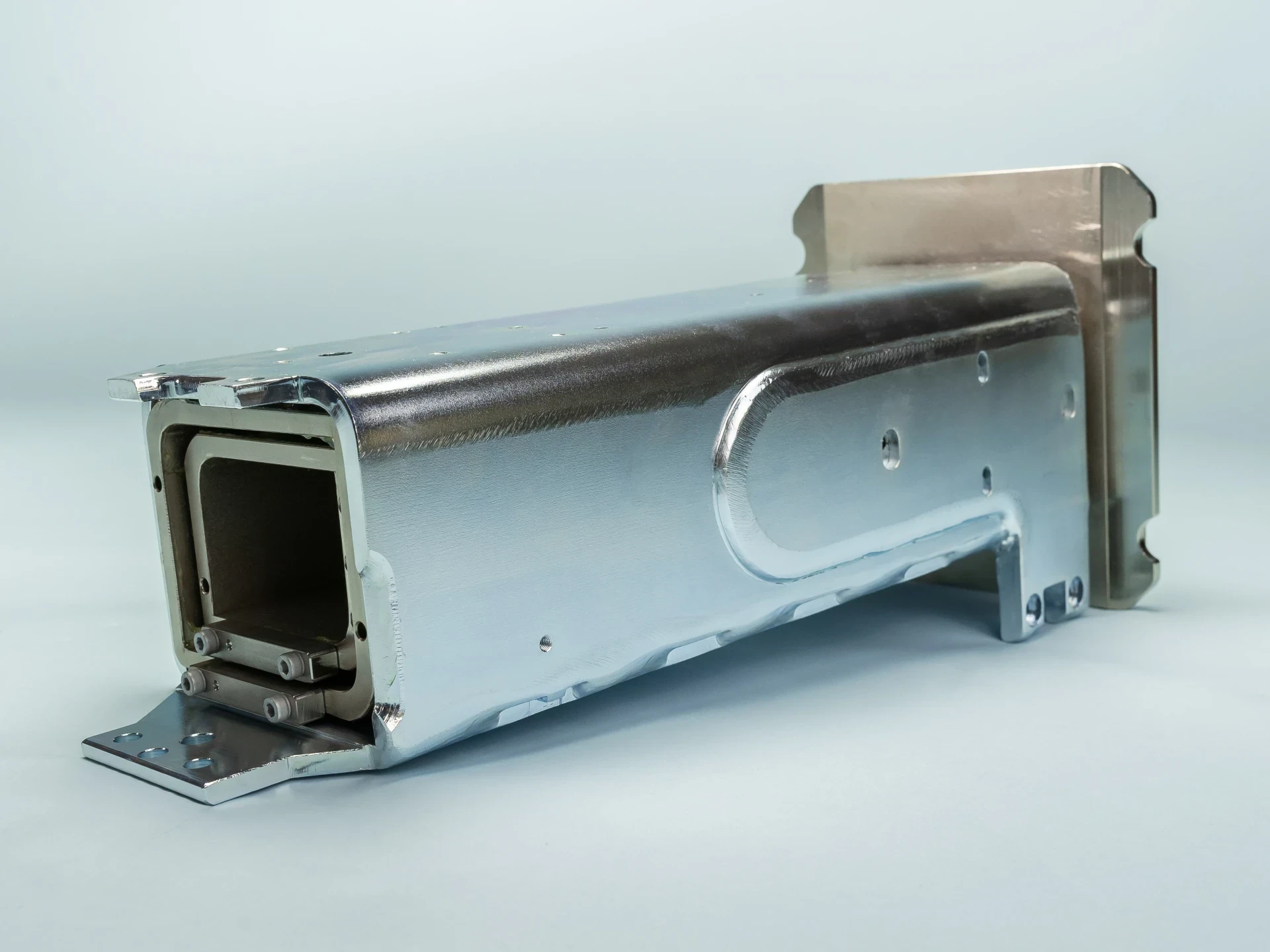

For pumps designed for firefighting vehicles, we performed surface treatment of an aluminum component using natural anodizing. This treatment provides corrosion resistance while maintaining the precise dimensional tolerances required for its proper function.

Assignment

The customer required anodizing of an aluminum pump component used to supply pressurized water during firefighting operations. The goal was to increase corrosion resistance and ensure surface stability, as the part is exposed to demanding conditions (frequent contact with water, high pressure, and harsh operating environments).

Used technology

An anodized layer with the specified thickness required by the customer was applied to the part. The process begins with cleaning and degreasing the surface to remove impurities and oxidation. This is followed by electrochemical anodizing in an acidic solution, during which an oxide layer forms on the surface. The surface is then rinsed and dried to ensure its stability and durability.

Result

After the anodizing process, the parts are corrosion-resistant, stable during long-term operation, and ready for installation in firefighting vehicles. The surface treatment meets all the customers technical requirements and contributes to the long service life of the components under extreme operating conditions.

Do you have a question for BOMEX?

Write us, and we will get back to you by the next working day.

Contact us via form or write us.