R.W.S., s.r.o.

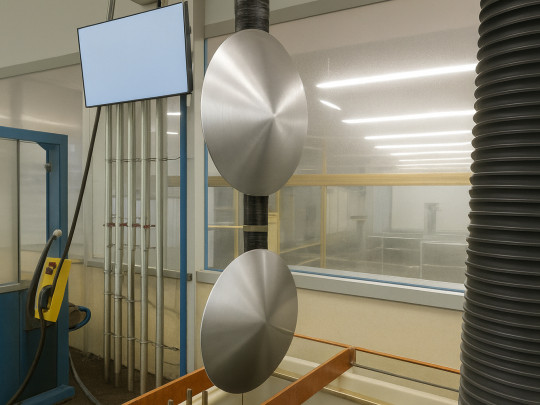

For the calotte part of a bridge bearing, we carried out a hard chrome plating surface treatment that ensures exceptional resistance to wear, corrosion, and heavy loads. Thanks to this process, the component has gained long service life and reliable performance, even under demanding bridge construction conditions.

Assignment

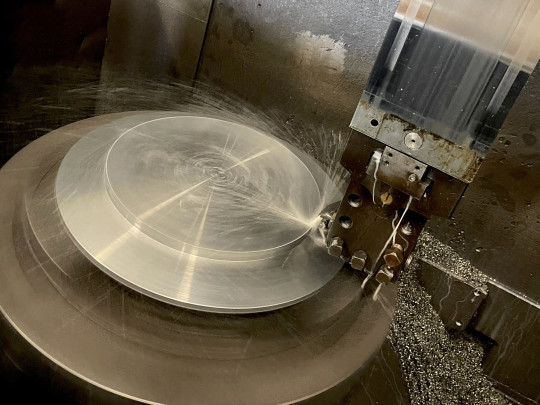

The goal was to provide a highly durable surface for the bridge bearing calotte that can withstand long-term mechanical friction, pressure, and environmental influences. The customer required the application of a precise hard chrome layer, as any deviation could affect the proper functionality of the bearing.

Used technology

A layer of hard chrome was applied to the steel calotte component, forming a durable and uniform surface coating. Before plating, the part was carefully cleaned, degreased, and masked according to the customer’s specifications. Hard chrome provides high surface hardness, smooth finish, and low friction, protecting the part against wear and corrosion. These properties make the surface ideal for extreme loads and dynamic forces commonly encountered in bridge bearing applications.

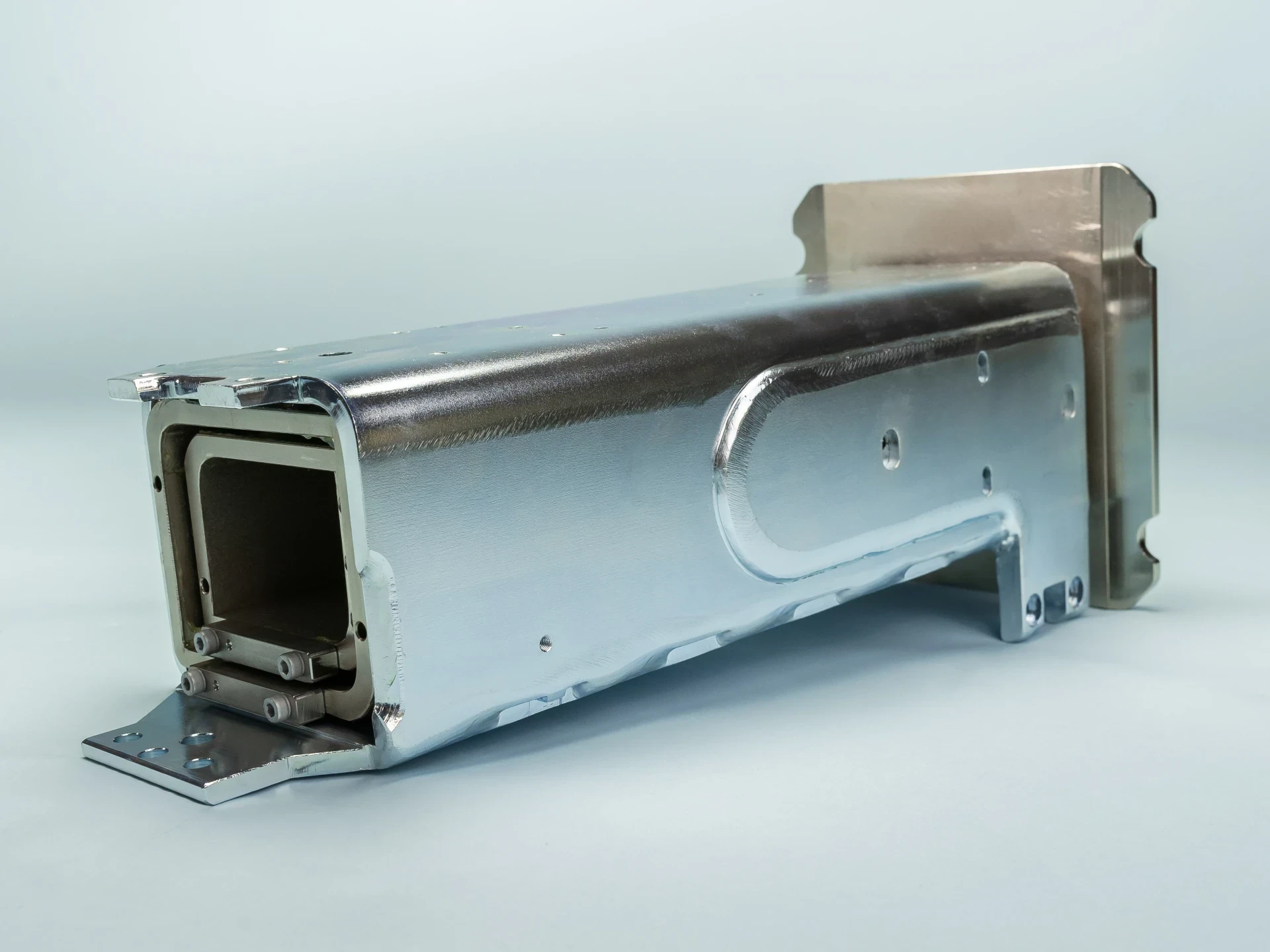

Result

The surface of the component now meets all technical requirements for precision and functionality within the bridge system. Thanks to the hard chrome plating, the calotte is highly resistant to wear, corrosion, and deformation, extending its service life while minimizing maintenance needs. The final surface features a high gloss and stable sliding properties, ensuring reliable performance of the bridge bearing even under long-term load conditions.

Do you have a question for BOMEX?

Write us, and we will get back to you by the next working day.

Contact us via form or write us.