ŠKODA JS, a.s.

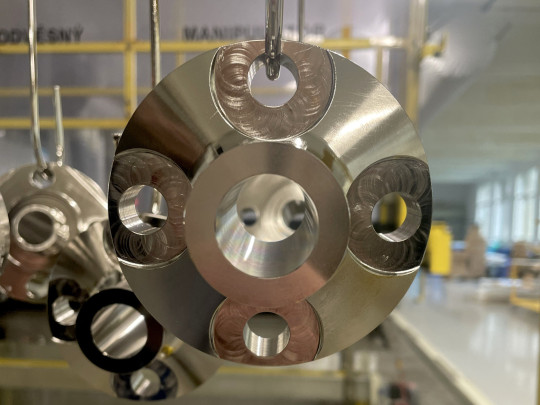

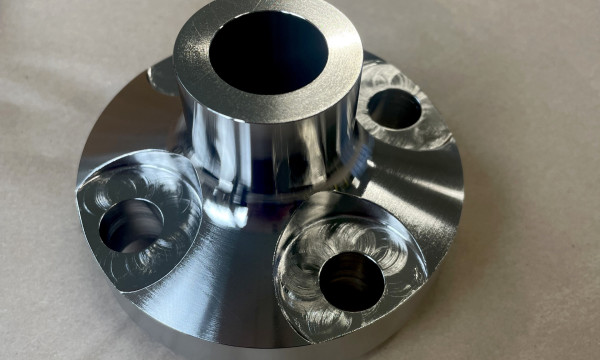

During the modernization of the steam generator nozzles at the Dukovany Nuclear Power Plant, a chemical nickel plating process with medium phosphorus content was applied. This surface treatment of the steel flange provides high corrosion resistance, uniform coating, and long-term operational reliability. Chemical nickel plating is an ideal solution for components exposed to extreme temperatures and pressures in the nuclear energy environment.

Assignment

The task was to apply a surface treatment to a steel flange intended for the modernization of the steam generator nozzles at the Dukovany Nuclear Power Plant. The requirements included achieving high corrosion resistance, uniform layer thickness, and excellent coating adhesion, while maintaining precise dimensional tolerances. The surface had to meet strict technical and safety standards of the nuclear industry.

Used technology

The flange was treated using chemical nickel plating with medium phosphorus content (6–9% P), a process particularly suitable for components with complex geometries. The electroless process allowed for uniform coverage of all flange surfaces, including holes, edges, and sealing areas, where precise layer thickness is critical for functionality and tightness.

Result

The resulting nickel layer with medium phosphorus content met the required thickness and exhibits high corrosion resistance and long-term stability, even at elevated temperatures. The flange fulfilled all technical specifications and was successfully incorporated into the installation process of the steam generator modernization.

This surface treatment significantly contributes to the safe and reliable operation of the Dukovany Nuclear Power Plant equipment.

This surface treatment significantly contributes to the safe and reliable operation of the Dukovany Nuclear Power Plant equipment.

Do you have a question for BOMEX?

Write us, and we will get back to you by the next working day.

Contact us via form or write us.