ASTRO KOVO PLZEŇ, s.r.o.

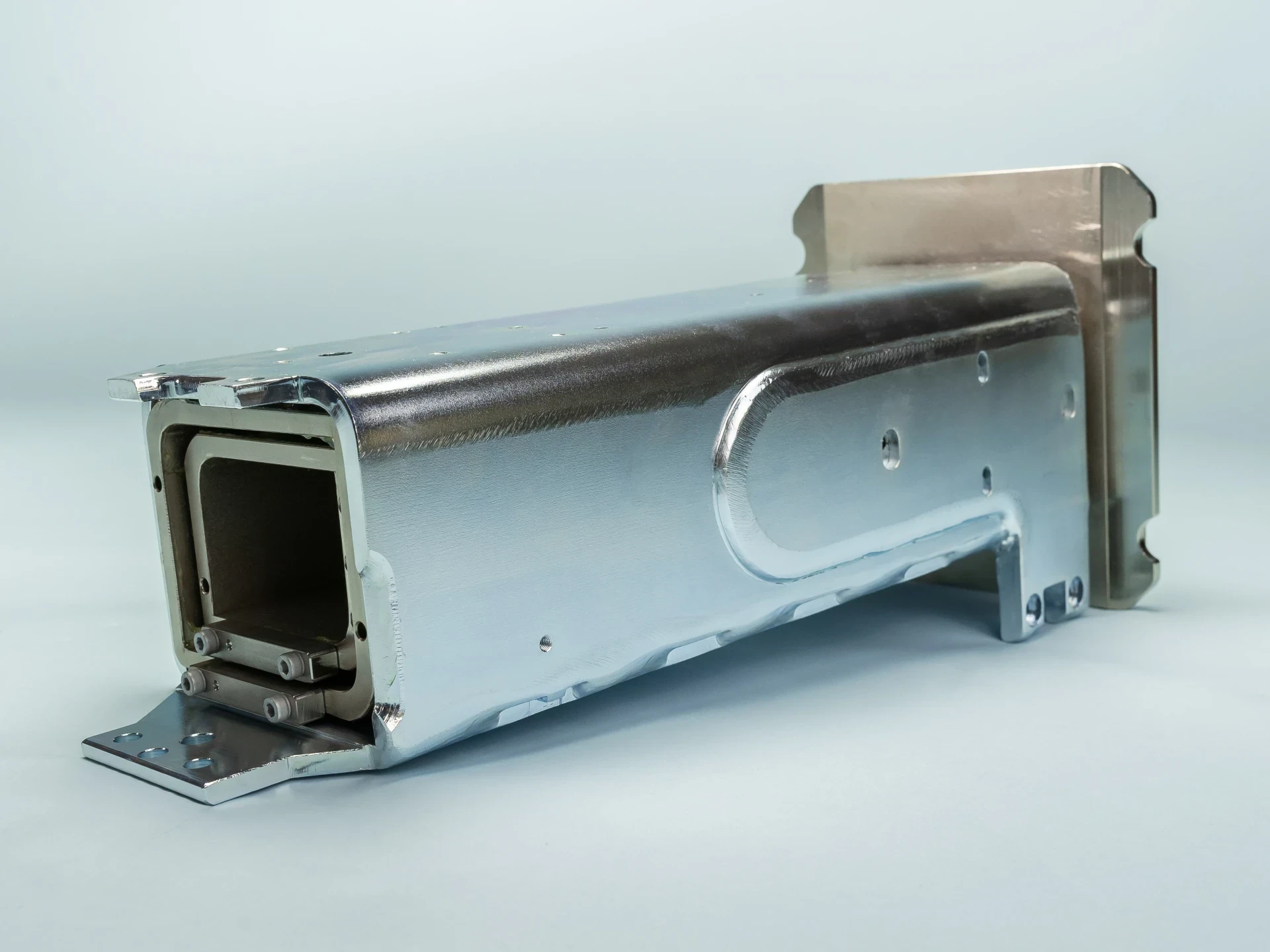

For the customer, we carried out black anodizing of an aluminum component with protected M3 threads. Thanks to precise machining and a uniform surface finish, the part is a fully functional element of the microscope measurement system, ready for reliable and accurate operation.

Assignment

The task was to perform a surface treatment on an aluminum part that is part of a microscope measurement system. The main requirements included high resistance to wear and corrosion, maintaining precise dimensions and tolerances, applying black anodizing with a uniform appearance, and, most importantly, protecting the M3 threads from being filled with the anodized layer to ensure full functionality.

Used technology

The process included precise cleaning and degreasing of the surface, thread protection, controlled anodic oxidation in a black electrolyte, and pore sealing to enhance mechanical and corrosion resistance. The result is a hard, homogeneous, and uniform surface layer that preserves the exact dimensions of the part and ensures reliable and precise function within the microscope measurement device.

Result

The finished component achieved a hard, homogeneous, and uniform surface layer with high wear and corrosion resistance, while precise dimensions and tolerances were maintained. The protected M3 threads remained fully functional, allowing for trouble-free assembly. As a result, the part is ready for reliable and precise operation as a component of the microscope measurement system.

Do you have a question for BOMEX?

Write us, and we will get back to you by the next working day.

Contact us via form or write us.