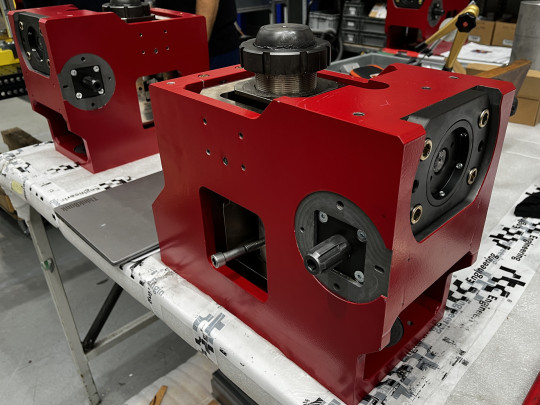

REVOL TT Consulting s.r.o.

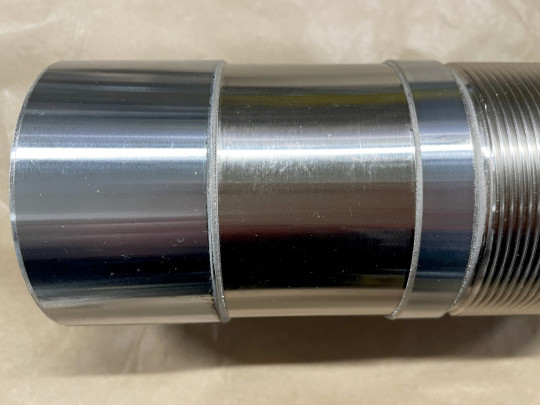

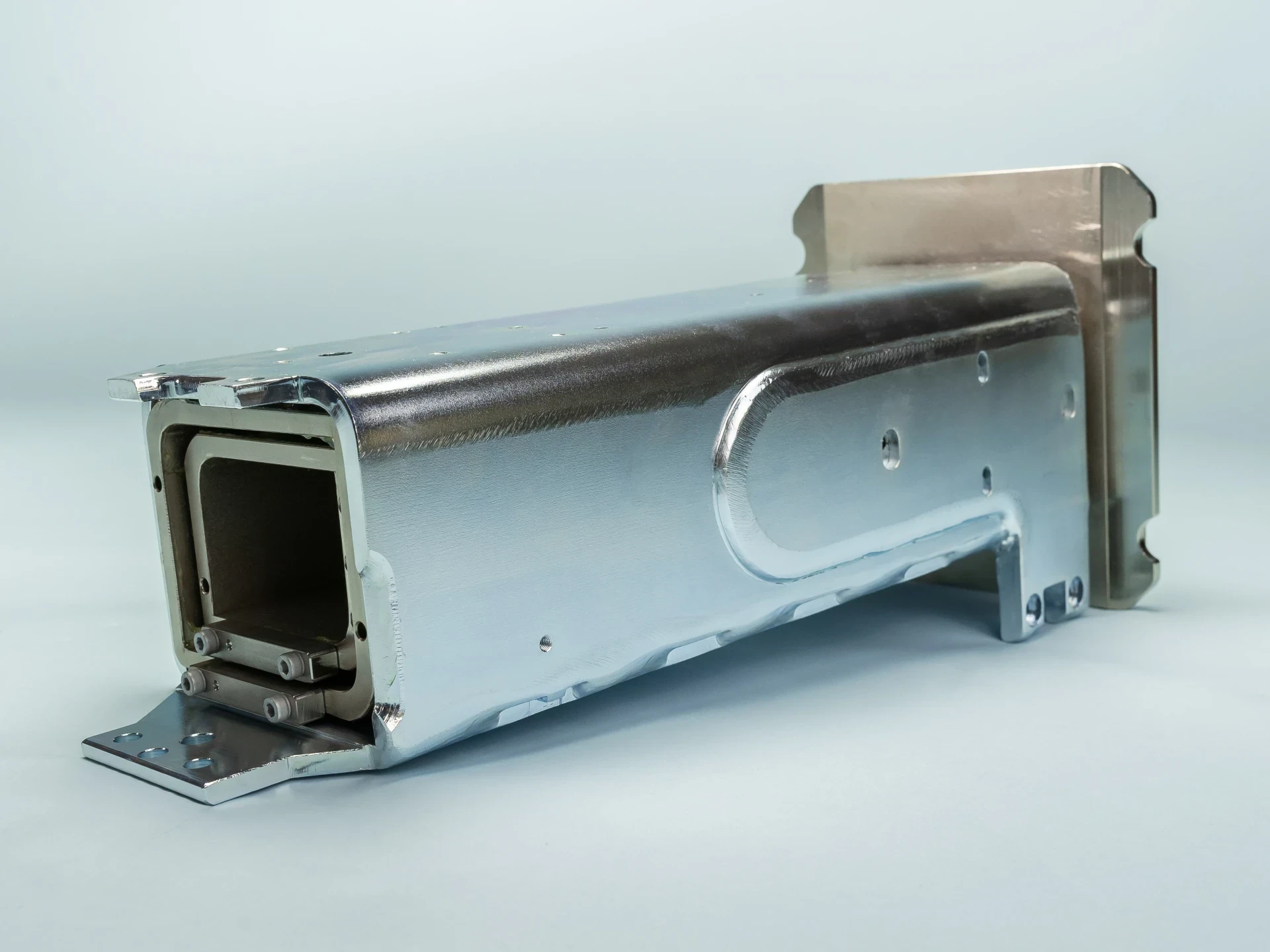

The subject of processing is a highly precise mechanical component intended for the gearbox of particle accelerator. The surface treatment is carried out in two stages: first, hard chrome plating is applied to the functional diameters, providing maximum wear resistance. After chrome plating, these surfaces are precisely masked, and other selected diameters are subsequently coated with a layer of high-phosphorus electroless nickel, which ensures uniform coverage and enhanced corrosion resistance. The combination of these technologies allows the component to meet the extreme requirements for precision, stability, and durability in the particle accelerator environment.

Assignment

The task is to ensure accurate and technologically controlled surface treatment of the component according to the engineering drawings. The process begins with the application of hard chrome plating to the designated functional diameters, with a focus on maintaining geometric accuracy and uniform layer thickness. After this operation, all chrome-plated areas must be carefully masked to provide full protection during subsequent processes. The remaining diameters are then coated with high-phosphorus electroless nickel, achieving the required thickness and uniformity without compromising the component’s functional tolerances. The entire process must ensure reliable adhesion of both layers and a stable surface.

Used technology

Hard chrome plating is carried out by electrolytic deposition of a chromium layer, providing high hardness, wear and corrosion resistance, and a low coefficient of friction. High-phosphorus electroless nickel is deposited autocatalytically, without electric current, ensuring uniform coverage of complex shapes and excellent corrosion resistance. The combination of these surface treatments provides optimal mechanical and chemical protection: hard chrome protects against wear and reduces friction, while electroless nickel ensures chemical stability and uniform coverage.

Result

The particle accelerator gearbox component is protected by hard chrome and high-phosphorus electroless nickel. This allows it to resist wear, corrosion, and high mechanical loads, ensuring reliable operation even under the most demanding conditions.

Do you have a question for BOMEX?

Write us, and we will get back to you by the next working day.

Contact us via form or write us.